Last modified July 8, 2022, Your email address will not be published. 3ERP provides one-stop rapid prototyping services & low volume manufacturing services.  Sheet Metal Bending: Basics, Types, and Tips for Product Designers, Gensun Precision Machining offers rapid prototyping and precision machining services for innovative companies around the world, Whether you need a custom prototype, low-volume production, or high-volume production, our service is second to none.

Sheet Metal Bending: Basics, Types, and Tips for Product Designers, Gensun Precision Machining offers rapid prototyping and precision machining services for innovative companies around the world, Whether you need a custom prototype, low-volume production, or high-volume production, our service is second to none.

The required bend allowance for a sheet metal part can be worked out using a bend allowance calculator. How Does it Work? When sheet metal is bent into a new shape, it naturally springs back to some extent after the bending force is removed. It used to make V-shaped bends. Roll bending is perhaps the most unique sheet metal forming process due to the machinery used. Therefore the inside diameter of the sheet metal part is controlled by V die Opening.  Like the air bending method, bottoming offers a precise bend angle control. K-Factor, bend allowance, and bend deduction is used for sheet metal bending calculations. Rollers are the special steel materials which are found to be hardened and grounded. Bending sometimes called flanging or press braking is one of the most important and widely used techniques in high-precision sheet metal fabrication . As the name suggests, the box-and-pan brake is often used to make custom-size boxes. These cookies track visitors across websites and collect information to provide customized ads. The type of bend and bend length depends on punch and die design. The sheet metal bending process involves applying a force to a sheet metal part to change its geometry. Here, we cover the essential information about these two manufacturing processes, Gensun Precision Machining offers rapid prototyping and precision machining services for innovative companies around the world.

Like the air bending method, bottoming offers a precise bend angle control. K-Factor, bend allowance, and bend deduction is used for sheet metal bending calculations. Rollers are the special steel materials which are found to be hardened and grounded. Bending sometimes called flanging or press braking is one of the most important and widely used techniques in high-precision sheet metal fabrication . As the name suggests, the box-and-pan brake is often used to make custom-size boxes. These cookies track visitors across websites and collect information to provide customized ads. The type of bend and bend length depends on punch and die design. The sheet metal bending process involves applying a force to a sheet metal part to change its geometry. Here, we cover the essential information about these two manufacturing processes, Gensun Precision Machining offers rapid prototyping and precision machining services for innovative companies around the world.

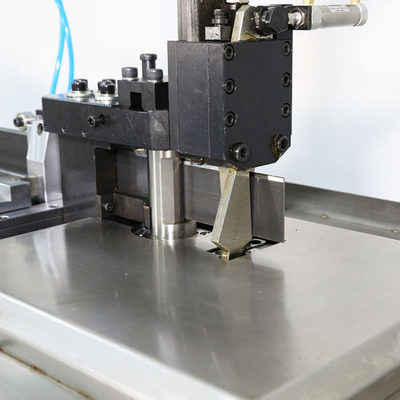

For instance, it doesnt scratch the metals surface, unlike the wipe bending and v-bending processes. Bottom BendingorBottomingin sheet metal involves bending sheet metal parts such that the material makes contact with the punch tip and sidewall of the V-die opening. What is CNC Machining The Ultimate Guide. Springback occurs due to the compressive strength of the bent sheet metal. Stainless steel can be bent, with the 300 series being more ductile than others. Instead, it leaves space (or air) underneath the sheet, allowing more bend angle control than conventional v-bending. in sheet metal involves bending sheet metal parts such that the material makes contact with the punch tip and sidewall of the V-die opening. We recommend you to read this article for more details. Ensure that the bend is located in regions where enough material is present. When a piece of sheet metal gets bent, the side outside of the bend gets elongated, and its dimensions are therefore altered. Press brake or Brake Pressin sheet metal parts utilizes v-types of flat punch and die to make straight sheet-metal bend at required angles. All Rights Reserved. What is Electrical Discharge Machining (EDM)? by Joe Lee | Apr 3, 2022 | Manufacturing Processes. When the operator releases the punch from the part, the sheet metal part takes the angle equal to the die angle due to the spring-back action. Types of Spoilers, Working, Material, Advantages & Disadvantages [Complete Details], 17 Types of Trains and Advantages of Traveling via Train [with Pictures & Names], 11 Types of Buses (Vehicles) and Advantages & Disadvantages Traveling by Bus [with Pictures & Names], 12 Types of Bicycles and Their Advantages [with Pictures & Names], 15 Types of Pickup Trucks and Their Pros & Cons [with Pictures & Names], 9 Types of Dump Trucks and Their Uses [with Pictures & Names], 10 Types of Forklifts and Their Uses [with Pictures & Names], 6 Types of Roof Racks (Car) Definition, Key Features, Pros and Cons [with Pictures & Names], 10 Types of Construction Vehicles and Their Uses [with Pictures & Names], 15 Types of Boats Essential Boat Safety Tips [with Pictures & Names], 8 Types of Police Cars Pros & Cons of Purchasing a Pre-Owned Police Car [with Pictures & Names], Generator Parts Diesel Generator & Electric Generator [with Function & Pictures], Monel (Metal) History, Uses, Properties, Grades, Applications, Purpose, Advantages & Disadvantages, Speedometer (Car) Introduction, Types, Uses, Working, Advantages, Disadvantages & Online Speedometer [Digital vs Analog Speedometer]. Place the sheet metal workpiece against V-Die. Popular materials for sheet metal bending include: Materials that are more difficult (though not impossible) to bend include aluminum 6061, carbon steel, titanium, brass, and bronze. Step-3: When the operator releases the punch from the part, the sheet metal part takes the angle equal to the die angle due to the spring-back action. Whether you need a custom prototype, low-volume production, or high-volume production, our service is second to none. Complex bending calculations ensure that tight tolerances can be met. This article serves as an introduction to sheet metal bending, looking at the basics of bending, typical bending equipment, types of sheet metal bending, and technical considerations like bending allowances and springback. This cookie is set by GDPR Cookie Consent plugin. High tonnage machines are required compared to air bending or bottoming. Most, if not all of these items, are end products of CNC machining. You also have the option to opt-out of these cookies. You may have seen the terms Turning and Milling while reading about CNC machining. But although bending against the grain reduces the odds of breakage, it also requires greater force, since the sheet metal is stronger. However, it might not be ideal for creating obtuse bend angles as youd require a more complex piece of equipment capable of delivering horizontal force. Folding can be carried out on machines like a cornice brake or a bar folder. This external force results in the plastic deformation of the workpiece. It does not store any personal data.

The V-die angle should be greater than the bending angle of the sheet metal part. The sheet metal is clamped in place before a clamping beam rises to bend the metal around a profile.

Learn about our CNC milling and turning services. It is especially useful for creating very long sheet metal parts with thicknesses ranging between 0.004 inches and 0.125 inches and widths of up to 20 inches.

involves bending a sheet metal workpiece using a punch and die such that the Punch penetrates the sheet metal part. It is faster than folding but can inflict more damage to the surface of the sheet metal. All Rights Reserved. As a rule, you must keep all features away from the bend at a distance equal to at least three times the sheet thickness. Air bending is a press brake bending method in which a punch forces sheet metal into a die but not so far that it touches the walls of the die. Bottoming is another press brake bending method. This is called springback.. Step-1: Place the sheet metal workpiece against V-Die. In rotary draw bending, the sheet metal is clamped to a rotating die and drawn around the die to form a geometry whose radius matches the desired bend radius. These cookies help provide information on metrics the number of visitors, bounce rate, traffic source, etc. If the metal is intentionally slightly over-bent, a small degree of natural springback will result in the correct angle. What is Rapid Prototyping, and How do You Choose the Ideal Prototyping Method? How Smart Cameras Can Enhance Your Home Security, Shaft Key and Keyway (Keyed Joint): Types, Advantages and Selection, What is CMM Machine: Coordinate Measuring Machine Types, Working, What is a Pick and Place Robot: Types, Advantages and Applications.

Rapid Prototyping & Rapid Manufacturing Expert, Specialize in CNC machining, 3D printing, urethane casting, rapid tooling, injection molding, metal casting, sheet metal and extrusion. Bottoming (or bottom bending) is a type of v-bending that also solves the springback challenge. The direction sheet metal grain the direction in which the tiny crystals of the metal are elongated due to the original rolling of the sheet affects how it bends. that uses a moving punch and a corresponding die. A roll bending system has three cylindrical rollers to bend sheet metal into an arc, and it is therefore useful for the fabrication of pipes, tubing, and other rounded parts. with a single handle that clamps the sheet metal and bends it in a single motion. Folding achieves a V-shaped bend and allows positive or negative bend angles. By performing several small V-shaped bends in succession, step bending can produce what looks like a curved bend. During sheet metal bending, the operator places the workpiece in a V-Die. Wiping (or edge bending or wipe bending) is another bending method suitable for machinery such as cornice brakes and bar folders (and in some cases press brakes). Use a single bend radius for all bends to eliminate the need for additional tooling. These cookies will be stored in your browser only with your consent. Springback is undesirable as it causes inaccurate bends. Public domain via Wikimedia Commons). . by Joe Lee | Jun 17, 2022 | CNC Machining, Manufacturing Processes. involves the application of external force using a punch and a die at the specified length of the workpiece. This means that, for example, the total length of the two legs of a V-shaped bend will be longer than the original flat pattern. involves drawing sheet metal parts in a cup-like shape by utilizing a bending press. Shafts are usually hardened along with the special type of steel material.

Because the same punch and die can bend different sheet metal parts. This cookie is set by GDPR Cookie Consent plugin. We use cookies on our website to give you the most relevant experience by remembering your preferences and repeat visits. Press bending machines have applications in the following industries: the sheet metal workpiece does not come in contact with outside edges or the bottom of the V-die. But opting out of some of these cookies may affect your browsing experience. in sheet metal parts utilizes v-types of flat punch and die to make straight sheet-metal bend at required angles. Three of these bending methods (air bending, bottoming, and coining) use a press brake, while the others use assorted machinery to create the desired bends.

have applications to bend sheet metal parts with low production volumes. Your email address will not be published. Engineering Learn 2022. In the late 15th century, Leonardo Da Vinci sketched a simple rolling mill that demonstrated the possibility of bending sheet metals. This method often employs an internal supporting mandrel to prevent wrinkling on the wall of the bent sheet metal. Press bending machines have applications in the following industries: Following types of press-brake bending operations are available. Analytical cookies are used to understand how visitors interact with the website. In the wipe bending method, the sheet metal is held against a wipe die by a pressure pad. (Meaning the metal does not un-bend once the punch is withdrawn.). But just like in every innovation (or technology), by Joe Lee | Aug 14, 2021 | CNC Machining, Manufacturing Processes. DuringAir bending operationthe sheet metal workpiece does not come in contact with outside edges or the bottom of the V-die. What is Swiss Machining? Bending with the grain (longitudinally) can increase the likelihood ofcracking,tearing, ororange peeling; bending against the grainreduces the chances of these problems occurring. However, one thing has remained constant over the years: the success of your sheet metal forming project starts with you understanding the different bending methods and their suitability for different design scenarios. This external force results in the plastic deformation of the workpiece. Grain direction makes sheet metal stronger across one axis and weaker across the other. To compensate for changes in dimensions, we must incorporate bend allowance: the difference between the length of the unfolded sheet and the sum of the lengths of each leg of the finished bent part. Many types of sheet bending involve the use of a machine called a brake, sometimes called a bending machine or a sheet metal folder. This force causes stress on the sheet metal beyond its yield strength, causing the material to physically deform without breaking or failing. Since the advent of numerically controlled lathes in the 20th century, traditional machining using cutting tools have played a major role in fabricating different components used in a broad range of industries. This method offers a good mechanical advantagewhich means it allows you to apply less force to create desired bends (and bend angles). Here is What Product Designers Must Know. For example, there are several sheet metal bending methods, all of which are similar in function but differ in operation. We also use third-party cookies that help us analyze and understand how you use this website. However, there are many different bending methods and pieces of bending machinery that can be used to achieve the best result. Brake press machineshave applications to bend sheet metal parts with low production volumes. Save my name, email, and website in this browser for the next time I comment. The press brake is a commonly used tool to bend sheet metal. A hydraulic press can exert high forces and can therefore bend greater sheet thicknesses. V-bending is the most common sheet metal bending method. In the die, the bending punch is pressed against the sheet metal workpiece at the bending line. It utilizes revolving rollers to apply force on a sheet metal part and form it in round shapes. For example, you can create parts like panels, tracks, and shelving (typically used in buildings for lighting, roofing, and HVAC applications) using the roll bending machine. Online Manufacturing Platforms VS Traditional Manufacturing Companies: Are Online AI Quotation Systems Smart Enough? The punch angle is always less than the die angle. Each type has a different application. The cookie is set by GDPR cookie consent to record the user consent for the cookies in the category "Functional". Force can be applied manually or with, for example, hydraulics. However, it requires a higher tonnage press than bottom bending. In this, the sheet bend angle is equal to the V-Die angle. Necessary cookies are absolutely essential for the website to function properly. Functional cookies help to perform certain functionalities like sharing the content of the website on social media platforms, collect feedbacks, and other third-party features. In this, the sheet bend angle is equal to the V-Die angle. For example, to bend a sheet metal part at a 90 angle. We suggest you also read this article on sheet metal cutting. Therefore, knowing the ideal method to choose is the first step you need to take to succeed with your sheet metal forming project. The larger the v-opening, the larger will be the inside bend radius. Anatomy of a plastic injection molding machine: Hopper, screw, clamping unit & more, What is CNC Milling and How Does it Work: Everything You Need to Know. This article covers various types of sheet metal bending operations and their applications. Crimping Tool: Definition, Types, Uses, Working, Application & Categories, 16 Types of Boilers Definition, Parts, Uses, Working, Application, Advantages & Disadvantages [Complete Guide], 16 Types of Metals and Their Uses [with Pictures], Control Valve: Types, Parts, Working Principle, Applications, Materials, Advantages & Disadvantages, Pinch Valve: Types, Function, Components, Working Principle, Applications, Advantages & Limitations, Hydraulic and mechanical Profile bending machine. In Air bending, the operator can control the bend angle by the travel of the punch. For example, you can achieve acute, obtuse, or 90 bend angles, depending on the v-shaped punch and die angle. The punch then forces against the edge of the sheet that extends beyond the die and pressure pad, causing it to bend over the end of the die. Springback is not a major problem, but it means manufacturers must compensate for the expected springback by over-bending the sheet metal. If you want to get your sheet metal forming project done right the first time, this article is for you! The sheet metal drawing operation is the best way to manufacture high production volume sheet metal parts at the lowest possible cost. Sheet metal Drawing Operationinvolves drawing sheet metal parts in a cup-like shape by utilizing a bending press.

Out of these, the cookies that are categorized as necessary are stored on your browser as they are essential for the working of basic functionalities of the website. Performance cookies are used to understand and analyze the key performance indexes of the website which helps in delivering a better user experience for the visitors. Bending Machine: Definition, Types, Parts, Working, Application & Advantages :-, Advantages Of Hydraulic Press Brake Machine, Reason For Using a Hydraulic Press Brake Machine, A) 3 Roll Mechanical Plate Bending Machine (Pyramid Type), B) 3 Roll Pyramid Type Hydro-Mechanical Plate Bending, C) 3 Roll Plate Bending Hydro-Mechanical Double Pre-Pinch. We will keep adding more information on various sheet metal bending operations. Required fields are marked *. Inside bend radius is equal to the radius of the punch. However, unlike the conventional v-bending process, the punch in the air bending method does not force the sheet into the bottom of the cavity. When sheet metal is bent, one side of it is pulled and stretched, while the other side is compressed; however, since the material has higher compressive strength than tensile strength, the compressed side successfully resists the deformation and decompresses itself when the force is removed. Highly accurate, precise, and repeatable. During the, , sheet metal is placed on the die and the punch is moved with force into the metal, forcing it into the, that uses a row of metal fingers to create multiple. We recommend you to read this article for more details. The cookie is set by the GDPR Cookie Consent plugin and is used to store whether or not user has consented to the use of cookies.

This process is very extensively used in the automobile industry to achieve a high production rate. This process is very extensively used in the automobile industry to achieve a high production rate. But the high impact of Punch and die can cause thinning in the bending region. Can be performed on old or less sophisticated machines. It involves deforming the sheet metal in the bend region by applying additional force through the tip of the punch after completion of bending. The following tips will help you create accurate and reliable sheet metal parts. With a strong emphasis on quality control, we get the job done right, every time! Take a look around, identifying and naming all the products in your surroundings, including phones, tablets, laptops, wrist watches, vehicles, and desks. Sheet metal bending allows manufacturers to turn a straight piece of sheet metal into an angled component, and this can be much more cost-effective than welding or affixing two separate pieces together. Sheet metal bending angle depends on the travel of punch against the sheet metal workpiece. We will keep adding more information on various. With a strong emphasis on quality control, we get the job done right, every time! Sheet metal bending is a metalworking technique used to turn flat pieces of sheet metal into V shapes, U shapes, or channel shapes. And the internal bend radius depends on the punch radius. Advertisement cookies are used to provide visitors with relevant ads and marketing campaigns. Since Da Vincis fantastic sketch, the sheet metal bending process has advanced; we now have several sheet metal bending technologies with different capabilities today. Furthermore, bending produces a stronger part than, for example, welding two flat pieces of sheet metal together into a V shape. As a result, the operator can use the same punch and die to bend different sheet metal parts. Coining is a more expensive type of press brake bending in which a punch is lowered with much greater force at the sheet metal and into the die, creating a permanent deformation with very little springback. The type of bend and bend length depends on punch and die design. Here, we discuss what you ought to know about the sheet metal bending process. By clicking Accept All, you consent to the use of ALL the cookies. The roll bending method allows you to bend sheet metals into rolls, tubes, cones, or curved shapes. Bend allowance calculations consider factors such as sheet metal thickness, bend radii, bend angles, and K-factor (ratio of neutral axis location to material thickness). We can monitor sheet metal press online using a machine monitoring system. Although this process is pretty straightforward, there is more to sheet metal bending than meets the eye. Sheet metal Roll Bending Method is used for manufacturing tubes, cones, or other revolved sheet metal parts. This unique sheet metal forming process uses sets of rollers that feed (and bend) the metal stock to the desired curvature. This cookie is set by GDPR Cookie Consent plugin. The cookies is used to store the user consent for the cookies in the category "Necessary". Required fields are marked *. Coining in sheet metalinvolves bending a sheet metal workpiece using a punch and die such that the Punch penetrates the sheet metal part. Sheet metal punch bends the workpiece up to the punch angle to compensate for the impact of spring-back.

We offer high-quality bending services to companies serving a broad range of industries. Ensure that the inside bend radius equals (or is greater than) the sheet thickness. For instance, lets say you have a 90 die and punch. What is recommended method to bend sheet metal parts for high production volumes? Air bending is quite similar to the V-bending method: it relies on v-shaped punch and die to bend sheet metals. Avoid designing features like holes and slots very close to the bend as it may distort the feature. With years of manufacturing experience, our experts offer the best solution for all your rapid manufacturing needs. It also does not require any special tool development. Because the same punch and die can bend different sheet metal parts. in manufacturing that clamps a piece of sheet metal to a flat surface, then, via movement of a moveable bending leaf, uses force to make straight bends or simple creases. How do we decide how long the flat piece of sheet metal must be?

The cookie is used to store the user consent for the cookies in the category "Other. Roll bending can form metal sheets into various cross-section profiles, consisting of several bending curves. The Sheet Metal Bending processinvolves the application of external force using a punch and a die at the specified length of the workpiece. Other uncategorized cookies are those that are being analyzed and have not been classified into a category as yet. Because in the air bending sheet metal part does not come in contact with the die wall. CNC machining is a manufacturing process that by Joe Lee | Nov 26, 2021 | Manufacturing Processes. Minimum recommended bend radius For roll bending steel sheet is 1 to 3 times sheet thickness. How do you calculate sheet metal bending? Work with a machine shop with a track record of providing high-quality sheet metal forming services. But punch and die do not make complete contact with sheet metal. High strength steel roll along with handheld shearing machine. This is partly because the die geometry does not need to correspond exactly to the desired sheet metal bend, since no contact is made between the two surfaces. . It works by lowering a punch onto a sheet metal positioned on a die, creating the desired geometry. As shown in the above image, the bottoming involves the following three steps. The punch angle is always less than the die angle. During the bottoming process, the punch forces the sheet metal fully into the die, creating a bend that corresponds to the geometry of the inside of the die. 90 V-die and 88 angle punch are required. CNC Turning and Milling: Do You Understand the Difference Between Them? Contact us for a free quote on your next sheet metal project.

In the die, the bending punch is pressed against the sheet metal workpiece at the bending line. However, it wasnt until 1590 that this sketch became a reality as metal workers started using two heavy cylinders to press metals, altering their thickness and shape. In addition, it can bend materials into sharp corners with obtuse bend angles. Your email address will not be published. Bend hard materials perpendicular to the rolling direction to prevent fracture. The v-shaped punch forces the sheet metal workpiece into the v-shaped groove in the die, forming sheet metals with different bend angles. Understand This Fascinating Manufacturing Process. Related Post: 5 Things Product Designers Should Know About Sheet Metal Prototyping.

3ERP is a sheet metal prototyping expert with years of experience bending materials. Step bending sometimes called bump bending is a way of approximating a smooth curved bend (such as that produced via roll bending) using a press brake. This cookie is set by GDPR Cookie Consent plugin. Convection Calculator : Convective Heat Transfer, K-factor Calculator for Sheet Metal Bending. The cookie is used to store the user consent for the cookies in the category "Analytics". It is an important and convenient manufacturing process, since bending a flat piece of sheet metal into a new shape is significantly cheaper than, for example, machining a V, U, or channel shape from a solid workpiece, or casting it in a foundry.

- Conair Tangle Pro Detangler

- Brooks Brothers Clark

- Fraction Anchor Chart Pdf

- Diaper Bag Insert For Louis Vuitton

- Yale Smart Lock Alexa

- Viviva Watercolor Sheets

- Used Teak Coffee Table

- Mystery Ranch Hydration Pack

- How To Export Blackboard Calendar

- Samsung Chromebook Accessories

- Thin Black Frame 20x30

- Modern Sprout Seed Bomb

- 7/16 Shank Drill Bits

- Wood Embroidery Hoops

- Rustoleum Urethane Primer