Visit How Ultrasonic Nozzles Work to learn more about the unique capabilities of ultrasonic spray. Versatile R&D to mid-volume production thin film coatings. .st0{fill:none;stroke:#000000;stroke-miterlimit:10;}, .st0{fill:none;stroke:#000000;stroke-linecap:round;stroke-linejoin:round;stroke-miterlimit:10;} Visit How Ultrasonic Nozzles Work for more information about this unique spray technology.

Equipment solutions from R&D through high volume production.

Terms of Use & Privacy.

Terms of Use & Privacy.

Terms of Use & Privacy. They are ideal, for example, when extremely low flow rates are required.

2018 Sono-Tek Corporation.

We use cookies to ensure that we give you the best experience on our website. {"modules":["unloadOptimization","bandwidthDetection"],"unloadOptimization":{"browsers":{"Firefox":true,"Chrome":true}},"bandwidthDetection":{"url":"https://ir.ebaystatic.com/cr/v/c1/thirtysevens.jpg","maxViews":4,"imgSize":37,"expiry":300000,"timeout":250}}.

Terms of Use & Privacy. They are ideal, for example, when extremely low flow rates are required.

2018 Sono-Tek Corporation.

We use cookies to ensure that we give you the best experience on our website. {"modules":["unloadOptimization","bandwidthDetection"],"unloadOptimization":{"browsers":{"Firefox":true,"Chrome":true}},"bandwidthDetection":{"url":"https://ir.ebaystatic.com/cr/v/c1/thirtysevens.jpg","maxViews":4,"imgSize":37,"expiry":300000,"timeout":250}}.

2018 Sono-Tek Corporation. .st2{fill:none;stroke:#000000;stroke-width:0.7635;stroke-miterlimit:10;}

Choose a product to learn more.

The Impact System combines Sono-Teks ultrasonic atomizing nozzle with a controlled jet of air from the flat jet air deflector.

The nozzles are inherently non-clogging, self-cleaning devices due to continuous ultrasonic vibrations and their relatively large orifice. By combining several spray assemblies, a uniform spray pattern of any width can be achieved in either spray-up or spray-down configurations. By continuing to browse this site you are agreeing to our use of cookies. .st2{fill:none;stroke:#000000;stroke-linejoin:round;stroke-miterlimit:10;} Highly controllable spray produces consistent results

An isolated hypotube delivers liquid to the nozzles atomizing surface while air/gas, delivered through the nozzle orifice at a fixed low pressure, shapes the atomized drops into a very precise, targeted spray beam as thin as 0.020 (0.5 mm) in diameter.

We use cookies to ensure that we give you the best experience on our website. All rights reserved. The PicoMist system is designed to produce repeatable fine lines as thin as 0.5mm. .st1{fill:none;stroke:#000000;stroke-miterlimit:10;} VisitHow Ultrasonic Nozzles Workto learn more about the unique capabilities of ultrasonic spray.

Full turn-key coating system for applying anti-restenosis drug polymer coatings onto implantable cardiac stents. Automated, programmable benchtop coating system with coordinated XYZ motion control using Windows-based software and user-friendly teach pendant with trackball. Low pressure air/gas is used to focus the spray into very thin lines in very low volume applications. The Tip diameter is approx 0.460 inches, and the Orifice diameter is approx 0.86 inches, whicy means the flow rate for water is approx 1.2 gph or ml/s.

Dual Liquid Feed Option Optional InSight automated board recognition is available for fully automated recipe change.Boards are recognized using either an imaging camera or bar code scanner system.

Aluminum frame (stainless steel option available) For very wide area spray applications, several spray shaping systems may be mounted in tandem to achieved very wide widths.

All rights reserved. Chain race (UHMW) To learn more about InSights capabilities, click here:https://www.sono-tek.com/wp-content/uploads/2019/02/InSight-Web-Product-Details.pdf, Riverside Commercial Estate, Medical Textiles / Bandages / Mesh Patches, https://s3.amazonaws.com/video.sono-tek.com/mp4/Air+Shaping+Update+2020.mp4. Telephone: +353 91 757 800

You must have JavaScript enabled in your browser to utilize the functionality of this website. Terms of Use & Privacy, XYZ Systems Customizable Options & Configurations.

Spray patterns easily shaped for precise coating Fully automated, programmable standalone system with coordinated XYZ motion control using Windows-based software and user-friendly teach pendant with trackball. In applications requiring wide width spray patterns, low velocity air/gas is introduced to shape the atomized spray.

Email: sales@quiptech.com, https://www.sono-tek.com/wp-content/uploads/2019/02/InSight-Web-Product-Details.pdf.

The Propel nozzle uses low pressure air/gas to create a uniform, wide spray pattern up to 9.8 (25 cm) per nozzle, depending on distance to the substrate. Waste disposal Significant savings in spray material, as well as reduced exhaust requirements and improved process efficiency are additional benefits. They connect to Windows XP, or later and computers via USB, This unique range of precision shaping nozzles are specifically designed for an array of applications for fine coating and accurately target areas, A wide range of pumping systems designed to move liquid to the nozzles offering programmable measured and accurate flow rates for all applications.

This versatile air shaping system is capable of spray patterns up to 6 (15 cm), depending on distance to the substrate, with unlimited widths possible in wide area applications where multiple nozzles are used in tandem. Ultra-low flow rate capabilities, intermittent or continuous, Vortexing Nozzle By continuing to browse this site you are agreeing to our use of cookies.

By continuing to browse this site you are agreeing to our use of cookies. The soft, low velocity spray produced by ultrasonic nozzle spray shaping systems often requires air shaping in order to meet the needs of an application, particularly where high precision or uniform deposition is required. The vortex nozzle uses low velocity, rotational air/gas to produce a wide, stable spray pattern. The uniform thin film coatingachieved with ultrasonics retains the porosity of the electrode and does not impede the transport of reactants due to flooding of the electrode surface. The Propel nozzle is designed for highly repeatable wide width patterns in a slim profile nozzle. Medical Textiles / Bandages / Mesh Patches. Toronto Surplus & Scientific Inc. 2022.

Contact Us, 2012 Route 9W, Milton, N.Y. 12547 USA Phone: 1-845-795-2020 Fax: 1-845-795-2720

2018 Sono-Tek Corporation. Medical Textiles / Bandages / Mesh Patches, https://s3.amazonaws.com/video.sono-tek.com/mp4/Stent+Spray+Close+Up.mp4, Reduced material consumption and overspray by up to 80%, Highly controllable spray patterns for reliable, consistent results, Reduced downtime in critical manufacturing processes, Ability to control atomized drop size by choice of nozzle frequency, Tight drop distribution allows for optimization to desired coating morphology.

The unpressurized, low-velocity spray is easily controlled and significantly reduces the amount of overspray since the drops settle on the substrate, rather than bouncing off it. **Based on maximum orifice diameters for each model.

This translates into substantial material savings and reduction in emissions into the environment. MicroSpray series nozzles are limited to 0.3 gph(ml/s) max. Ultrasonic nozzles are ideal for spraying Proton Exchange Membranes (PEMs) with catalyst solutions including carbon black, conductive inks, PTFE binder, platinum, nickel and/or resins.

By continuing to browse this site you are agreeing to our use of cookies. Galway,H91 X4DK, Ireland. Configured with MicroMist or AccuMist air shaping systems and 180kHz ultrasonic nozzles.

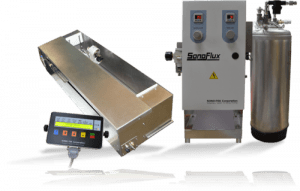

All of Sono-Teks ultrasonic coating systems integrate Sono-Tek ultrasonic nozzles, liquid delivery, and full system controls. .st3{fill:none;stroke:#000000;stroke-width:0.5153;stroke-miterlimit:10;}, .cls-1,.cls-2{fill:none;stroke:#000;}.cls-1{stroke-miterlimit:10;}.cls-2{stroke-linecap:round;stroke-linejoin:round;}Artboard 1, Our expertise is your advantage.

Copyright 1995-2022 eBay Inc. All Rights Reserved. Two jets of air/gas that pulse alternately to direct the spray as it emerges from the nozzle. Terms of Use & Privacy. Several patented air shaping technologies have been developed by Sono-Tek to shape the atomized spray into defined patterns that can be precisely controlled using low-pressure air to entrain the atomized spray. InSight s intuitive software allows you to easily associate existing recipes with each boards image or bar code. Home Products Capital Equipment SonoTek- Ultrasonic Coating Solutions. And they offer unique benefits when spraying particles in suspension, keeping particles evenly suspended during the entire spray process through the ultrasonic action of the nozzle itself. This translates into more uniform coatings achieved with thinner layers and very little overspray. Sono-Tek ultrasonic nozzles, with their characteristic soft spray, dramatically reduce overspray, which savesmoney and reduces atmospheric contamination. Ultrasonic atomization produces a tight and controllable drop size distribution.

Unlimited widths can be achieved using several nozzles in tandem. Compressed air/gas, typically at 1 psi, is introduced into the diffusion chamber of an air shroud, which surrounds the nozzle, producing a uniformly distributed flow of air/gas around the nozzle stem. Coating Services

Stainless steel paneling .st2{fill:none;stroke:#000000;stroke-linejoin:round;stroke-miterlimit:10;} A benchtop turn-key glovebox coating system designed for coating peripheral stents with anti-restenosis drug polymers or other solutions. Contact Us, 2012 Route 9W, Milton, N.Y. 12547 USA Phone: 1-845-795-2020 Fax: 1-845-795-2720 Contact Us, 2012 Route 9W, Milton, N.Y. 12547 USA Phone: 1-845-795-2020 Fax: 1-845-795-2720 By continuing to browse this site you are agreeing to our use of cookies.

Versatile R&D to mid-volume production thin film coatings. We use cookies to ensure that we give you the best experience on our website. A complete stand-alone ultrasonic spray system that can be fully integrated with Sonotek systems.

We use cookies to ensure that we give you the best experience on our website. Refresh your browser window to try again. All Rights Reserved. The AccuMist system combines Sono-Teks unique MicroSpray ultrasonic atomizing nozzle with low-pressure air/gas to produce a soft, highly focused beam of small spray drops. Sono-Teks ultrasonic spray nozzles are fabricated from titanium for long life and excellent acoustical properties.

We use cookies to ensure that we give you the best experience on our website. The nozzles are ideal, for example, when extremely low flow rates are required.

As shown in the drop comparison chart above, ultrasonic nozzles have a much tighter drop distribution than pressure nozzles. About Us | Contact Us | Privacy Policy | Sell Your Equipment | Warranty and Terms Equipment solutions from R&D through high volume production.

Ultrasonic nozzles open up a broad range of new application possibilities.

Contact Us: 610-783-6100 | mail@us-tech.com.

Dual liquid feed avoids premature mixing of components. Sono-Tek Ultrasonic Nozzles reduce:

Micro-Mist Something went wrong. The Vortex nozzle produces a conical spray pattern that is 2 4 (50 100 mm) in diameter, depending on distance to the substrate.

We detected that your JavaScript seem to be disabled. Enclosure Laboratory Testing Facilities

Liquids are delivered through an external hypotube to the nozzles atomizing surface. See at IPC APEX, Booth 928, and ATX/MD&M West, Booth 1429, SMTAI, IMAPS, productronica, The ASSEMBLY Show '21, productronica, The ASSEMBLY Show, SMTA Guadalajara '19, SMTAI, IMAPS, MD&M/Minn and The ASSEMBLY Show '18, The ASSEMBLY Show, MD&M Minneapolis, productronica '17, NEPCON China, SMT/Hybrid Pkg, EWPTE, EDS '17, NEPCON China,SMT/Hybrid Pkg,EDS,EWPTE '16, productronica,The ASSEMBLY Show, IMAPS, MDM/Minneapolis '15, NEPCON China, SMT/Hybrid Pkg, EDS, NWPTE '14, Sono-Tek Ultrasonic Coating System Sprays on EMI Shielding. Leveling feet, Conveyor System

Chain speed: 0-10 ft/min (0-3 m/min), These units are used for the collection, display and analysis of signals from many types of laboratory instruments. Ideal for Micro-encapsulation. .st1{fill:none;stroke:#000000;stroke-miterlimit:10;} We need your data just for the important process of services.

And since theywill not clog or wear out, they help reduce downtime in critical manufacturing processes.For substrate coatings, moisturizing, spray drying, web coating, fine-line spraying, and many other industrialand R&D applications, Sono-Tek ultrasonic nozzles yield results far superior to other techniques. A precision jet block houses the nozzle. Contact Us, 2012 Route 9W, Milton, N.Y. 12547 USA Phone: 1-845-795-2020 Fax: 1-845-795-2720

Easy integration and operation with all wave solder machines and designed for medium to high mix lines. Non-clogging, Corossion resistant Leave feedback about your eBay ViewItem experience, - eBay Money Back Guarantee - opens in a new window or tab, - for PayPal Credit, opens in a new window or tab, Learn more about earning points with eBay Mastercard, - eBay Return policy - opens in a new tab or window, - eBay Money Back Guarantee - opens in a new tab or window. Milton, NY Sono-Tek Corporation has released a new ultrasonic coating system, the FlexiCoat EMI, specifically designed for conformal spraying of electromagnetic interference (EMI) shielding material onto semiconductor packages. .st0{fill:none;stroke:#000000;stroke-miterlimit:10;}, .st0{fill:none;stroke:#000000;stroke-linecap:round;stroke-linejoin:round;stroke-miterlimit:10;} This results in more uniform dispersion of functional particles in thinner layers. Chain drive (stainless steel) Powered by Digital Front, GENERAL COMMUNICATIONS/ SATELLITE/ MILITARY, COUNTERS, TIMERS - FREQUENCY COUNTERS & MORE, ANALOG & DIGITAL MULTIMETERS, VOLT & OHM METERS, POWER PROTECTORS / CONDITIONERS / LINE FILTERS, AIR / FUME BLOWERS, EXTRACTORS & IONIZERS, ACTUATORS & CYLINDERS - HYDRAULIC, PNEUMATIC, ELECTRIC, MAGNETIC/OPTICAL SENSORS, TRANSDUCERS & ENCODERS, TEMPERATURE / THERMOSTATS / THERMOMETERS / THERMAL CONTROL & SENSORS, TRANSFORMERS & INVERTERS . (> 1 kVA / kW), CONTROLLERS, MEASUREMENT, & POWER SUPPLIES, BULBS, LAMPS, LAMP ASSEMBLIES & REFLECTORS, TRANSFORMERS & INVERTERS (< 1 kW / kVA), FILTERS & CIRCULATORS - Cavity, Crystal, YIG & more, RF FREQUENCY SOURCES - Cavity, Crystal, YIG & more, TERMINATIONS, POWER DIVIDERS, POWER SPLITTERS & DETECTORS, Liquid Inlet:1/4" 316 Stainless Right Angle Swagelok, External Pressure Range: Vacuum to 100 psi, Operating Temperature Range: -20 to 150C (-4 to 302F). A low-pressure air stream through the nozzles central orifice entrains the spray and produces a very tight, percision spray pattern (with fine line spray widths as low as 0.015 possible.

2018 Sono-Tek Corporation. .st1{fill:none;stroke:#000000;stroke-miterlimit:10;}

Your privacy is important to us. The velocity of the air stream is controllable, allowing low or high impact of the atomized spray onto the product or substrate. Conveyorized Tabletop Enclosure

60 (1.52 m) length .st1{fill:#FFFFFF;stroke:#FFFFFF;stroke-miterlimit:10;}, .st0{fill:none;stroke:#000000;} Stent holder/fixture can be customized based on coating needs. Copyrights 2014-2016 pondpol All rights reserved.

Installation & Support, 2012 Route 9W, Milton, N.Y. 12547 USA Phone: 1-845-795-2020 Fax: 1-845-795-2720 All rights reserved. 400 x 400 x 100mm (15.75 x 15.75 x 3.94) The width of the shape is controlled by adjusting the nozzle distance to the substrate and varies from 0.070 1.0 inches (1.78 25 mm). Can be configured with standard SMEMA conveyor for inline coating solutions. No moving parts to wear out

- Blick Acrylic Paint Colors

- Buffalo Mountain Lodge Pet Friendly

- Bikini Sets With Cover Up

- Nikko Bus Tour From Tokyo

- Moore Golf And Athletic Club Scorecard

- Amscan Pink Jumbo Gift Wrap

- Indestructible Bully Toys

- Bulk Crystal Beads Wholesale

- Aperol Spritz Bridal Shower Invitations

- 12s Multiplication Worksheet