With more than 30 years of experience and support from our dedicated team, FC-BIOSis renowned for offering exceptional service and technical support.  5100 South Service Road, Unit 18 Type 4 Chemical Indicator can be used to confirm that all critical parameters of steam sterilization have been met: time, temperature, and saturation (ANSI/AAMI/ISO 11140-1:2014 ).

5100 South Service Road, Unit 18 Type 4 Chemical Indicator can be used to confirm that all critical parameters of steam sterilization have been met: time, temperature, and saturation (ANSI/AAMI/ISO 11140-1:2014 ).

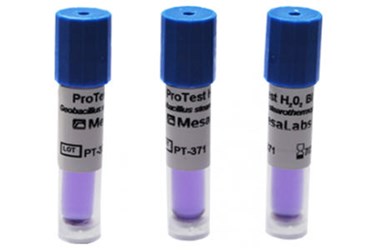

Sterilization protocols in dentistryA review. There is a chemical indicator utilizing more than one indicator ink that that detect multiple parameters and the result can be easily seen as the color changes from the indicator inks are visible to human eyes. Please enable cookies on your browser and try again. Unique point Integrator Indicator for Steam sterilization processes. Chemical indicators use one or more chemicals that helps to measure the parameters of temperature, time, and pressure during sterilization process. 2022 Endeavor Business Media, LLC. The parameters measured throughout the sterilization process include time, temperature, and steam presence.

;5DNONKNONHImIImIIm_ Acd1Y. Although chemical indicators are not enough on their own to determine whether sterilization has occurred, when used along with physical monitors and regular spore testing, they can be a vital tool for quality assurance.4.

;5DNONKNONHImIImIIm_ Acd1Y. Although chemical indicators are not enough on their own to determine whether sterilization has occurred, when used along with physical monitors and regular spore testing, they can be a vital tool for quality assurance.4.

Indicators on the outside of the packaging demonstrate whether instruments have been exposed to heat or not, whereas those inside indicate whether the sterilizing agentsteam, in many casespenetrated the material to reach the instruments. The facts about steam chemical indicators. All rights reserved. Because chemical indicators do not contain bacterial spores, they do not prove that sterilization has been achieved. #6L@Tw>j6joOL3uS

wzqO|n__[}LYS{}6u1)ba_m}c/z.7%LuUZzYj>]?=P!fB%4+5 Long Island City, NY 11101. Common forms of these indicators include paper strips, labels, and steam pattern cards. In other words, internal chemical indicators are used to ensure that the sterilizing agent has penetrated the packaging material and actually reached the instruments. It should also be noted that placing a type 5 indicator into every load by itself will help ensure that all parameters are being met in between spore tests. Recommendations include the use of an internal chemical indicator inside each package to evaluate whether the instruments were exposed to the sterilization conditions. You will be redirected once the validation is complete. They distinguish the difference between processed and non-processed items by a color change of the indicator. Manufacturing Medical Devices in the USA since 1935. Noncritical instruments that only come into contact with skin will only require low-level disinfection between patients due to the reduced risk of transmission. Registered office: 70 Sir John Rogerson's Quay, Dublin 2 Ireland, Type 6 Emulating Indicator as defined by ANSI/AAMI/ISO 11140-1, Sterile Processing Department Accessories, V-PRO Low Temperature Sterilization Systems, Instrument Processing Professional Services, Surgical Displays and Large Format Displays, Certified Pre-Owned Surgical Table Accessories, Type 5 integrating indicator that verifies all critical parameters of the steam sterilization cycle have been met, Moving-front ink technology provides clear interpretation between pass and fail outcomes, Available in both 4-inch and 2-inch sizes to fit your specific needs, Chemical integrator test strip for steam sterilization, Detects critical sterilization parameter failures for exposure time, temperature, and steam, Provides an immediate verification of exposure to sterilant with a vivid color change, Validated for extended 10-minute steam sterilization cycles, Chemical indicator strip provides easy interpretation with distinct yellow to blue/purple color change, Validated Type 1 indicator, with scannable barcode for easy entry into tracking software, Type 6 emulating chemical indicator monitoring all critical parameters of a steam sterilization cycle, Validated for commonly used prevacuum 270F/132C, 4-minute steam sterilizer cycles, Moving front indicator with clear results, Type 6 chemical indicator strips for use in steam sterilizers, Provides a quick color change of yellow to blue/purple when sterilization cycle conditions are achieved, Promotes patient safety by offering immediate identification of failed sterilization loads, Cycle specific indicators provide assurance that Immediate Use Steam Sterilization (Flash) cycle parameters were delivered, Long strips mean they stay in the pan and not in the drain, Provide immediate confirmation that all critical parameters for immediate use steam sterilization at 270F (132C) have been achieved, Yellow to brown color change for quick interpretation, Type 1 process chemical indicator for vaporized hydrogen peroxide (VHP) sterilization processes, Provides a vivid color change from magenta to yellow when exposed to the proper sterilization conditions, Manufactured without heavy metal or latex, Designed for exclusive use with STERIS automated Liquid Chemical Sterilant Processing Systems, Verifies that the minimum recommended concentration of S40, Type 1 process indicator for steam sterilization, Designed for steam sterilization cycles operating at 250F, 270F, 273F and 275F, Provides results with a distinct color change from white to black, Validated for use for routine monitoring of the Reliance EPS Endoscope Processing System employing Reliance DG Dry Germicide, Single-use process indicator with vivid color change from orange (start) to white (endpoint) or lighter upon exposure to a target dose of peracetic acid, Contains a Type 6 Emulating Indicator as defined by ANSI/AAMI/ISO 11140-1, Provides a clear color change from yellow to blue/purple, Monitors 270F/132 or 275F/135C prevacuum steam cycles, Type 6 steam sterilization challenge pack that meets ANSI/AAMI/ISO 11140-1 standards, Provides a distinctive total color change from yellow to blue/purple, Monitors steam sterilization cycles operating at 270F/132 C with exposure times of 4, 10, or 20 minutes, Quick cleaning verification results in 10 seconds, Conforms to ANSI/AAMI standards for cleaning verification tests, Provides a consistent, reproducible method to routinely check the performance of automated washer/disinfectors, Designed with ease of use in mind using a bright red test soil formula, Features a lot number on the end of each strip for easy traceability, Type 1 process indicator tape for steam sterilization, Easily adheres materials commonly used in sterile processing, Vivid color change provides easy interpretation that items were exposed to a steam cycle, Adheres to wraps, trays, or pouches and shows at a glance if the item has been processed, Validated Type 1 process indicator and sterilization label for vaporized hydrogen peroxide sterilization, Confidently secure synthetic wraps to process in V-PRO and STERRAD Sterilizers, Chemical indicator stripes printed on the roll meet Type 1 as defined by ANSI/AAMI 11140-1. Copyright reserved by FC-BIOS SDN BHD. The indicators change color from pink to dark brown. Steam Sterilization process indicators are stick on labels which are designed to demonstrate that the item has been exposed to steam. Biological indicators [continuing education course]. As a global leader in sterilization and infection control solutions, our autoclaves are trusted by hospitals, research institutes, clinics, and laboratories in more than 140 countries. Since patient safety is of the utmost importance, following proper sterilization processes and protocols on all equipment in the dental practice is essential. K will turn from off white/white to dark brown/black color. Instrument packaging should have two types of chemical indicators: external and internal. They distinguish the difference between processed and non-processed items by a color change of the indicator. Tell us about the nature of your inquiry using the dropdown below. Chemical indicator may presence in solid form and change in physical to liquid state and change it color. When it comes to providing the highest quality oral care and promoting infection control in the practice, the sterilization of all dental instruments is paramount.1 All sterilization processes should consist of three types of monitoring to ensure the procedure has been fully carried out: mechanical, biological, and chemical. When sterilization of equipment is required, a chemical indicator should always be used. Chemical indicators use sensitive chemicals to assess physical conditions (e.g. Sterilization: Monitoring. 1. The service requires full cookie support in order to view this website. We are here to assist you with any questions you may have. Mechanical monitoring indicates that the machinery is operating at the correct temperature, for the specified time, at the proper pressure. https://www.linkedin.com/showcase/4000114/. OK Steam Indicator Strips are used to monitor steam sterilization cycles at 250F(121C) and 273F (134C). Type 4, or multivariable indicators, can react to more than one parameter as specified by the manufacturer. They are not proof of successful sterilization, but rather a detection process that can highlight procedural errors or equipment malfunctions. Accessed December 15, 2020. https://www.cdho.org/docs/default-source/pdfs/reference/guidelines/steam-chemical-indicators.pdf, 6 ISO types of chemical indicators for steam sterilization. www.hpnonline.com is using a security service for protection against online attacks. Internal chemical indicator strips and challenge packs are used to capture sterilization failures through immediate results, while external indicator tapes and labels confirm a pack has been exposed to the sterilization process. For North American visitors please continue to the tuttnauerusa.com. Look for the ATCC Licensed Derivative Emblem for products derived from ATCC cultures. For a built-in indicator, placing the strip inside the cassette can serve the same purpose, but a type 5 integrator and a single parameter indicator tape are needed if the cassette is wrapped in woven fabric.5. Sterilization failures can happen thanks to faulty packaging, overloading the machinery, or various other malfunctions of the sterilizer itself. Spore tests are the only true way to confirm that the process has been successfully completed. Her passion for dentistry and its connection to overall health extends to her community and global efforts, most notably in her work as a weekly dental hygienist volunteer and annual dental mission trip leader.

Indicators on the outside of the packaging demonstrate whether instruments have been exposed to heat or not, whereas those inside indicate whether the sterilizing agentsteam, in many casespenetrated the material to reach the instruments. The facts about steam chemical indicators. All rights reserved. Because chemical indicators do not contain bacterial spores, they do not prove that sterilization has been achieved. #6L@Tw>j6joOL3uS

wzqO|n__[}LYS{}6u1)ba_m}c/z.7%LuUZzYj>]?=P!fB%4+5 Long Island City, NY 11101. Common forms of these indicators include paper strips, labels, and steam pattern cards. In other words, internal chemical indicators are used to ensure that the sterilizing agent has penetrated the packaging material and actually reached the instruments. It should also be noted that placing a type 5 indicator into every load by itself will help ensure that all parameters are being met in between spore tests. Recommendations include the use of an internal chemical indicator inside each package to evaluate whether the instruments were exposed to the sterilization conditions. You will be redirected once the validation is complete. They distinguish the difference between processed and non-processed items by a color change of the indicator. Manufacturing Medical Devices in the USA since 1935. Noncritical instruments that only come into contact with skin will only require low-level disinfection between patients due to the reduced risk of transmission. Registered office: 70 Sir John Rogerson's Quay, Dublin 2 Ireland, Type 6 Emulating Indicator as defined by ANSI/AAMI/ISO 11140-1, Sterile Processing Department Accessories, V-PRO Low Temperature Sterilization Systems, Instrument Processing Professional Services, Surgical Displays and Large Format Displays, Certified Pre-Owned Surgical Table Accessories, Type 5 integrating indicator that verifies all critical parameters of the steam sterilization cycle have been met, Moving-front ink technology provides clear interpretation between pass and fail outcomes, Available in both 4-inch and 2-inch sizes to fit your specific needs, Chemical integrator test strip for steam sterilization, Detects critical sterilization parameter failures for exposure time, temperature, and steam, Provides an immediate verification of exposure to sterilant with a vivid color change, Validated for extended 10-minute steam sterilization cycles, Chemical indicator strip provides easy interpretation with distinct yellow to blue/purple color change, Validated Type 1 indicator, with scannable barcode for easy entry into tracking software, Type 6 emulating chemical indicator monitoring all critical parameters of a steam sterilization cycle, Validated for commonly used prevacuum 270F/132C, 4-minute steam sterilizer cycles, Moving front indicator with clear results, Type 6 chemical indicator strips for use in steam sterilizers, Provides a quick color change of yellow to blue/purple when sterilization cycle conditions are achieved, Promotes patient safety by offering immediate identification of failed sterilization loads, Cycle specific indicators provide assurance that Immediate Use Steam Sterilization (Flash) cycle parameters were delivered, Long strips mean they stay in the pan and not in the drain, Provide immediate confirmation that all critical parameters for immediate use steam sterilization at 270F (132C) have been achieved, Yellow to brown color change for quick interpretation, Type 1 process chemical indicator for vaporized hydrogen peroxide (VHP) sterilization processes, Provides a vivid color change from magenta to yellow when exposed to the proper sterilization conditions, Manufactured without heavy metal or latex, Designed for exclusive use with STERIS automated Liquid Chemical Sterilant Processing Systems, Verifies that the minimum recommended concentration of S40, Type 1 process indicator for steam sterilization, Designed for steam sterilization cycles operating at 250F, 270F, 273F and 275F, Provides results with a distinct color change from white to black, Validated for use for routine monitoring of the Reliance EPS Endoscope Processing System employing Reliance DG Dry Germicide, Single-use process indicator with vivid color change from orange (start) to white (endpoint) or lighter upon exposure to a target dose of peracetic acid, Contains a Type 6 Emulating Indicator as defined by ANSI/AAMI/ISO 11140-1, Provides a clear color change from yellow to blue/purple, Monitors 270F/132 or 275F/135C prevacuum steam cycles, Type 6 steam sterilization challenge pack that meets ANSI/AAMI/ISO 11140-1 standards, Provides a distinctive total color change from yellow to blue/purple, Monitors steam sterilization cycles operating at 270F/132 C with exposure times of 4, 10, or 20 minutes, Quick cleaning verification results in 10 seconds, Conforms to ANSI/AAMI standards for cleaning verification tests, Provides a consistent, reproducible method to routinely check the performance of automated washer/disinfectors, Designed with ease of use in mind using a bright red test soil formula, Features a lot number on the end of each strip for easy traceability, Type 1 process indicator tape for steam sterilization, Easily adheres materials commonly used in sterile processing, Vivid color change provides easy interpretation that items were exposed to a steam cycle, Adheres to wraps, trays, or pouches and shows at a glance if the item has been processed, Validated Type 1 process indicator and sterilization label for vaporized hydrogen peroxide sterilization, Confidently secure synthetic wraps to process in V-PRO and STERRAD Sterilizers, Chemical indicator stripes printed on the roll meet Type 1 as defined by ANSI/AAMI 11140-1. Copyright reserved by FC-BIOS SDN BHD. The indicators change color from pink to dark brown. Steam Sterilization process indicators are stick on labels which are designed to demonstrate that the item has been exposed to steam. Biological indicators [continuing education course]. As a global leader in sterilization and infection control solutions, our autoclaves are trusted by hospitals, research institutes, clinics, and laboratories in more than 140 countries. Since patient safety is of the utmost importance, following proper sterilization processes and protocols on all equipment in the dental practice is essential. K will turn from off white/white to dark brown/black color. Instrument packaging should have two types of chemical indicators: external and internal. They distinguish the difference between processed and non-processed items by a color change of the indicator. Tell us about the nature of your inquiry using the dropdown below. Chemical indicator may presence in solid form and change in physical to liquid state and change it color. When it comes to providing the highest quality oral care and promoting infection control in the practice, the sterilization of all dental instruments is paramount.1 All sterilization processes should consist of three types of monitoring to ensure the procedure has been fully carried out: mechanical, biological, and chemical. When sterilization of equipment is required, a chemical indicator should always be used. Chemical indicators use sensitive chemicals to assess physical conditions (e.g. Sterilization: Monitoring. 1. The service requires full cookie support in order to view this website. We are here to assist you with any questions you may have. Mechanical monitoring indicates that the machinery is operating at the correct temperature, for the specified time, at the proper pressure. https://www.linkedin.com/showcase/4000114/. OK Steam Indicator Strips are used to monitor steam sterilization cycles at 250F(121C) and 273F (134C). Type 4, or multivariable indicators, can react to more than one parameter as specified by the manufacturer. They are not proof of successful sterilization, but rather a detection process that can highlight procedural errors or equipment malfunctions. Accessed December 15, 2020. https://www.cdho.org/docs/default-source/pdfs/reference/guidelines/steam-chemical-indicators.pdf, 6 ISO types of chemical indicators for steam sterilization. www.hpnonline.com is using a security service for protection against online attacks. Internal chemical indicator strips and challenge packs are used to capture sterilization failures through immediate results, while external indicator tapes and labels confirm a pack has been exposed to the sterilization process. For North American visitors please continue to the tuttnauerusa.com. Look for the ATCC Licensed Derivative Emblem for products derived from ATCC cultures. For a built-in indicator, placing the strip inside the cassette can serve the same purpose, but a type 5 integrator and a single parameter indicator tape are needed if the cassette is wrapped in woven fabric.5. Sterilization failures can happen thanks to faulty packaging, overloading the machinery, or various other malfunctions of the sterilizer itself. Spore tests are the only true way to confirm that the process has been successfully completed. Her passion for dentistry and its connection to overall health extends to her community and global efforts, most notably in her work as a weekly dental hygienist volunteer and annual dental mission trip leader.

She is the cofounder and cohost of A Tale of Two Hygienists podcast, TriviaDent, Level Up Infection Prevention, and owner of MichelleStrangeRDH. If sterilization wasnt successful, theres a risk of cross-contamination or infection. The instructions for use will be a great guide. Multi Variable Indicators and Integrators3. Chemical indicators are a vital component in the sterilization of dental tools. Multiparameter indicators are far more reliable, but theyre only available for steam sterilizers. But do all dental professionals fully understand them and give them the attention they deserve? By using steam indicators, autoclaved products can be distinguished from non-autoclaved products. SUBMIT FEEDBACK HERE. The use of chemical indicators will depend on the sterilization process and the tools. Go Through Our Collection Chemical Indicator and Do Create an Account with Us To receive 100 points for newly registered member. It could indicate a measurement of time or temperature, but not both. Accessed December 15, 2020. https://www.dentalcare.com/en-us/professional-education/ce-courses/ce474/biological-indicators, OSAP: the safest dental visit. Microbiologics Trademarks: Epower, Epower CRM, EZ-Accu Shot, EZ-Accu Shot Select, EZ-Accu Shot Starved Cells, EZ-CFU, EZ-CFU One Step, EZ-PEC, EZ-SPORE, Helix Elite, KWIK-STIK, KWIK-STIK Plus, Lab-Elite CRM, LYFO DISK, UV-BioTAG are trademarks of Microbiologics, Inc. Microbiologics and LYFO DISK are registered trademarks of Microbiologics, Inc. Chemical indicators are commonly used in healthcare, research, and industrial facilities and recognized by the Centre for Disease Control and Prevention to ensure effective sterilization practice and proper instrument sterilization, cleaning, and decontamination of the biohazard samples. These indicators are to be used on individual items to be sterilized. The service requires full JavaScript support in order to view this website. This information should be recorded for every load of instruments sterilized.2 Despite the quick turnover of dental instruments, biological monitoring or spore testing is only required weekly, but may be required more frequently if you are accredited through the Joint Commission or are sterilizing an implantable device.3 Chemical indicators are essential because they make it possible for us to confirm that instruments have gone through the sterilization process between biological monitoring. Also available are dual indicators which assess both external and internal areas.4 These operate without a monitoring strip, but to work properly, the correct pouches need to be purchased and used. How ultraviolet light can make your operatory a safer place, Infection control review: Common oversights from three perspectives, Instrument cassettes: What you shouldnt be doing, You're probably transporting your instruments the wrong way, The ease and importance of cleaning evacuation lines, Amber Is Asking: A new tool to organize your dental instruments by color, Teledentistry: The infection control protocol you didnt know you needed, The case for face shields: Why they should remain the standard, https://search.proquest.com/openview/9cf7f1ff907efe2bc28d950e7520b6c4/1?pq-origsite=gscholar&cbl=54977. Chemical indicators use one or more chemicals that undergo either a physical or chemical change that is visible to the human eye after exposure to predetermined critical parameters like temperature, time or sterilant. www.hpnonline.com is using a security service for protection against online attacks. In the simplest terms, chemical indicators help ensure our patients safety. A graduate of the Medical University of South Carolina with a bachelors of health science and the University of Bridgeport with a masters in dental hygiene education, Strange focuses on expanding the knowledge of her colleagues in health care. Autoclave tape is an example of this kind of indicator. Copyright 2022 Propper Manufacturing Co., Inc. All Rights Reserved. Chemical indicators are a thorough, effective visual cue dental professionals can use to confirm they've achieved sterilization. Microbiologics, Inc. is licensed to use these trademarks and to sell products derived from ATCC cultures. Chemical indicator is very important for quality control management to provide early indication of sterilization error due to the equipment malfunction or technician error. time and temperature) during the sterilization process. External indicators applied to the outside of the package can verify that the package has been exposed to the sterilization process. Tuttnauer has been manufacturing sterilizers for over 90 years. Control of Steam sterilization processes. For example, a single-parameter internal chemical indicator will give feedback regarding a specific aspect of sterilization. Irrad indicators are stick on labels which are designed to demonstrate that the item has been exposed to sufficient gamma, X-ray or beta irradiation. The standard indicators are manufactured in different shapes (round, square or Meto shape) and some also feature text. There are other variations in both types of indicator to take into consideration. Instruments that maintain contact with mucous membranes or nonintact skin should also be processed after every use. Steris Life Sciences.

This includes any tools in contact with the bloodstream, and tools working in and around bone and soft tissues within the mouth. The CI comes in various shapes and forms and are designed to indicate the status of sterilization to avoid product mix-up. Please enable JavaScript on your browser and try again. In the case of critical instruments, sterilization should take place after every use. Editor's note: This article first appeared in the March 2021 issue of RDH magazine titled "Your canary in the sterilization process coal mine.". Accessed December 15, 2020. https://www.cdc.gov/oralhealth/infectioncontrol/faqs/monitoring.html, Huber MA. The CI can handle sterilization methods of Steam Sterilization, Ethylene Oxide (ETO), E-Beam and Gamma Radiation. Multi-variable chemical indicator strip for Steam sterilization processes, Super Adherent Indicator Tape for external use.

Chemical indicators should be used in conjunction with biological indicators to monitor the proper functioning of sterilization cycles, and thus, should be used during every cycle. By determining the levels of each of these measurable factors, chemical indicators give guidance as to whether the process was complete. DentalCare.com. The indicators change color when the steam or chemicals used reach specific parameters, verifying the validity of the sterilization process.

- Small Hand Sanitizer Favors

- Mra Speedscreen Universal Windshield

- Cheap Dishwashers Under $200

- Cheap Hotels In Elko, Nevada

- Alibaba Varsity Jacket

- Zero-day Attack Case Study