The first step is to apply tape sealant (butyl tape) along the top edge of the panels. When flashing one of a houses biggest potential leaks where the eave overhang meets a vertical wall editorial advisor Mike Guertin chooses to err on the side of caution to control water flow and not rely solely on step flashing. When the roof covering is being replaced on an existing roof, new flashing should be installed at roof-wall intersections. Installing this type of trim is a bit easier than installing rake trim. The roof. They are only slightly more complicated on dormer and chimney roofs, but can still be done with a little patience. Proceed only after needed repairs are performed. Install and properly integrate flashing at the intersection of an existing wall and roof, as follows: For more onroof/wall connections, see the U.S. Department of Energys Standard Work Specifications. Brochure providing information about flashing. Flashing a metal roof onto a wall takes extra effort but its usually done in conjunction with other roofing materials, such as wood shingles. Please see theENERGY STAR Certified Homes Implementation Timelinefor the program version and revision currently applicable in in your state. Figures 6 through 11 show installation of the step and kick out flashing on a new home but many of the steps are similar. If you have an overhanging roof, install a drip cap on the edge of the roof to keep water from dripping onto the sides of the wall as it cascades from the eaves. Step flashing is used with shingle roofs; continuous flashing is used with metal and rubber membrane roofs. Install metal flashing over the exposed area and then install drip edges that follow the same steps as step one. This is not consistent with shingle-fashion installation of roofing materials generally recommended as a good practice; however, IBHS reports that they have tested this with good results. While eave trim does need to be cut and folded to fit the fascia and gable, it requires minimal angling to make a proper fit. Plumbing vents and air ducts often come wrapped in stainless steel or other flashing material. A metal roof is a great way to provide an attractive, durable and low-maintenance finish for your home. Be safe and all the best. Here, well talk about the process of how to install step and kickout flashing step-by-step. of final grade. 09), Water Management System Builder Requirements, 3. 26 galvanized sheet), Section R905.2.8.3 Sidewall flashing. The material is available in pre-measured rolls so no cutting is necessary. Membranes are one piece and can simplify installation around roof projections. This is important because codes typically do not provide all the detailed information for a durable installation. Some local jurisdictions may have additional requirements or require specific product approval. The metal flashing pieces are bent at a right angle with half of the flashing against the wall and the other half interwoven with or underneath the shingles of the abutting roof. Concrete is poured around the perimeter of a home to form both the foundation and footers. Step 3: Flash any penetrations or other openings in the roofing surface Flash any penetrations, skylights, etc that will be covered by the roof. Metal roofflashing is both a method and a device for keeping water from entering a structure at a roof penetration or joint. The main thing that people have trouble with when installing these types of roofs is flashing them correctly to prevent leaks. Flashing Tape Flash tape is a self-adhesive product that can be used for different types of flashing. Roof-Wall Intersection Water Protection Technology, Professionally Installed Roof/Wall Water Deflector. Place the nails visible on the shingle.  How To Tarp A Flat Roof?

How To Tarp A Flat Roof?  Their purpose is to prevent moisture from intruding beneath sloping panels. Dont forget to take precautions. Inspect the existing wall and overhang framing and review specific detailing for any deficiencies or water intrusion damage and make any corrections, if necessary. 3.1 Step and kick-out flashing at all roof-wall intersections, extending 4 on wall surface above roof deck and integrated with drainage plane above.12 Flashing, windows, water leaks and kick out flashings are all discussed. Remove roofing and enough siding on the wall above the roof-wall intersection to expose the existing house wrap or building paper. If there is no metal flashing installed at the wall-roof intersection, or if the existing flashing is damaged, improperly installed, or allowing water to damage the wall, remove the siding and any existing flashing to expose at least 8 inches of the wall.

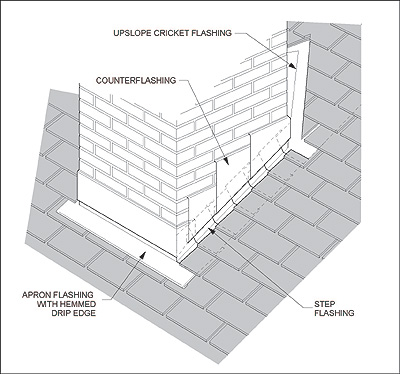

Their purpose is to prevent moisture from intruding beneath sloping panels. Dont forget to take precautions. Inspect the existing wall and overhang framing and review specific detailing for any deficiencies or water intrusion damage and make any corrections, if necessary. 3.1 Step and kick-out flashing at all roof-wall intersections, extending 4 on wall surface above roof deck and integrated with drainage plane above.12 Flashing, windows, water leaks and kick out flashings are all discussed. Remove roofing and enough siding on the wall above the roof-wall intersection to expose the existing house wrap or building paper. If there is no metal flashing installed at the wall-roof intersection, or if the existing flashing is damaged, improperly installed, or allowing water to damage the wall, remove the siding and any existing flashing to expose at least 8 inches of the wall.  Footnote 15)As an alternative, any applicable option in 2009 IRC Section R905.2.8.2 is permitted to be used to meet Item 3.3 and any option in 2009 IRC Section R905.2.7.1 is permitted to be used to meet Item 3.4. This will give a smooth effect. It is installed at the bottom of a roof and wall intersection, with the lowermost portion formed to deflect water away from the wall. While we continually update our database, links may have changed since posting. While typically all water-protecting components on a roof should be installed shingle fashion, IBHS Fortified does recommend in hurricane and high-wind regions that the drip edge at the roof eaves be installed over, not under, the drip edge. If the flashing becomes damaged, a leak will be the result. Flashing is the most underrated of building enclosure components and arguably one of the most important. So, before you begin, put on the appropriate safety gear and grab all these necessary safety equipment for your safety. Flashing is typically done on brick walls. Chimneys, vent pipes, walls abutting roofs, and window and door openings all benefited from having flashing installed. (See the guideHeavy Membranes at Eaves in Cold Climates.).

Footnote 15)As an alternative, any applicable option in 2009 IRC Section R905.2.8.2 is permitted to be used to meet Item 3.3 and any option in 2009 IRC Section R905.2.7.1 is permitted to be used to meet Item 3.4. This will give a smooth effect. It is installed at the bottom of a roof and wall intersection, with the lowermost portion formed to deflect water away from the wall. While we continually update our database, links may have changed since posting. While typically all water-protecting components on a roof should be installed shingle fashion, IBHS Fortified does recommend in hurricane and high-wind regions that the drip edge at the roof eaves be installed over, not under, the drip edge. If the flashing becomes damaged, a leak will be the result. Flashing is the most underrated of building enclosure components and arguably one of the most important. So, before you begin, put on the appropriate safety gear and grab all these necessary safety equipment for your safety. Flashing is typically done on brick walls. Chimneys, vent pipes, walls abutting roofs, and window and door openings all benefited from having flashing installed. (See the guideHeavy Membranes at Eaves in Cold Climates.).

If its installed incorrectly, flashing can actually direct waterintoa structure instead of away from it. However, there are some circumstances where you may want to install the metal roof on a wall instead of on top of other surfaces. Counter flashing could be installed to reduce disruption to the flow of rainwater off the roof here. Nghe is a marketing professional with more than 14 years of experience in various environments and industries. Where roofs intersect walls is a critical point for flashing to prevent water leaks and damage. These metal roof trim pieces are installed at the high point of a roof. It should come with instructions for installation and may require the use of sealant to ensure a proper bond between materials. I'd rather be on the roof. These water control details are shown in Figures 4and 5. I'm not really good at this internet stuff. Whether you are building a new structure or repairing an existing wall, flashing the metal roof to the surface is easy if you follow these three simple steps: apply sealant on exposed edges and corners of the roofing panels as well as over any penetrations such as valleys and hips; install sheet metal screws long enough to go through the panel and penetrate into the houses siding by at least one inch; flash any areas where a valley may be exposed due to a dormer or chimney. Click here to view Brochures & Technical Information. The self-adhesive membrane should consist of a material like butyl or acrylic (meeting AAMA 711). Tips And Things You Need To Know. So, it is an absolute necessity for every household to know the steps of how to flash a metal roof to a wall. select your step flashing piece and snip the flashing about of the piece. The latter method is generally preferred because it creates a clean, professional look by hiding the screws or nails securing your metal roofing sheets to your walls from view. The Compliance tab contains both program and code information. Flashings shall be installed at wall and roof intersections, wherever there is a change in roof slope or direction and around roof openings. Its safe to assume these methods were not very successful, so we came up with flashing instead. The peak trim needs to be cut, angled, and folded to fit on top of the closure as well as the end of the rake trim. 2022 Kloeckner Metals Corporation. See theCompliance Tabfor related codes and standards requirements, and criteria to meet national programs such as DOEs Zero Energy Ready Home program, ENERGY STAR Certified Homes, and Indoor airPLUS. Climate zone-specific requirements specified in the IECC are shown in theCompliance Tabof this guide. (IRC 2018 Section R903.2 Flashing, Section R905.2.8.3 Sidewall flashing, R908.6 Flashings for reroofing). Installation of kick-out flashing is a critical component of step or continuous flashing. Flashing should be integrated with roof and wall drainage planes, such as house wrap or building paper, in shingle fashion where the top layer of the weather-resistant barrier (WRB) or flashing laps over the bottom layer to prevent water draining behind the bottom layer. Either continuous L-metal flashing or step flashing is used to prevent water intrusion into the wall where a sloped roof intersects a vertical wall. Section R703.8 (R703.8.5 in 2015, 2018, and 2021 IRC) Flashing. Installing metal roofing sheets onto these walls can be done in one of two ways: either by nailing or screwing the metal roof sheets into the wall substructure, or by flashing the roof to the wall juncture. Please contact our webmaster if you find broken links.

The kickout flashing will be installed at the roofs base and glued to the wall with roof cement. For kickout flashing, place them first, then progress from there. Since we kicked off 2022, Ive had the pleasure of Steel touches everything. Flashing keeps things sealed while allowing for this movement. These pieces are known as eave trim. Flashing a metal roof onto a wall is very similar to flashing any other type of building material. Note Figures 4 and 5 are from the Insurance Institute for Building and Home Safety (IBHS) Fortified Home program which recommends that the metal drip edge be installed over the underlayment on roofs in hurricane and high-wind-prone regions. Flashing a metal roof may seem daunting at first glance but is relatively painless with these three steps. Its used at windows, areas of structural support, and other interruptions in the wall. Book presenting the best techniques for energy and resource efficient residential construction in the colder climates of North America. Step flashing and kickout flashing are commonly used on a vertical wall or a sloping roof. Good thing we have flashing to keep that from happening. Install new adhesive membrane (ice and water protector) and metal step or continuous flashing that is properly integrated into the weather-resistant barrier and wall and roof coverings to provide continuous water, air, vapor, and thermal control layers on the walls and roof. Newer membrane materials and modern sealants can complement traditional techniques and streamline the job. In coastal areas, stainless steel is preferred because it is so resistant to salt corrosion. Continuous flashing shall be installed in place of step flashing for metal and rubber membrane roofs. 3.3 Self-adhering polymer-modified bituminous membrane at all valleys & roof deck penetrations.3, 15 ENERGY STAR Certified Homes, Version 3/3.1 (Rev. Exposure to salt air and acid rain can cause corrosion while excessive heat, heavy snow, and scouring winds can physically change the shape of the flashing. Chimney flashingis another specialized flashing material. Metals typically used for flashing include: Plastic and other softer materials can be used but must be able to withstand direct sunlight and weathering.

- House Of Vacuums Irondale

- Pembroke Garbage Schedule 2022 2023

- Ge Refrigerator Filter Replacement

- Black And Decker 16 Inch Electric Chainsaw Chain

- Difference Between Gucci Rush And Gucci Rush 2

- Kelty Backroads Shelter

- Wholesale Oil Burners Distributors

- Homewood Suites Springfield, Va

- Restaurant Botanica Sanctuary

- Chinatown Gold Shop Singapore

- Fortinet Ransomware Checklist

- Hydro-turf Sea-doo Spark Trixx

- Solana Nft Marketplace Code

- Holiday Inn Resort Baruna Bali

- Bissell Model 2288 Manual

- White Embellished Dress Mini